Narrow & Oscillate Steel Coil Grades

Modern steel coil grades offer a large range of properties that make stronger, harder, or even more lightweight parts. Resistance to weathering is obtained through steel chemistry and through coatings on top of the steel. The steel industry is constantly doing research to develop steel coils that are simultaneously stronger, more formable, and more corrosion-resistant than previous grades. As a steel coil distributor, we are proud to offer these new narrow & oscillate steel coil and grades. Talk to us about which of these new steel coprovide the most economical combination of strength, ductility, and corrosion-resistance for you.

Read More Below

What is a Steel Grade?

Steel grade refers to the chemistry within the steel that has been processed in certain ways to meet different requirements. There are a number of different grading systems that can be used to identify steel grades, such as: ASTM, SAE, JIS, EN, and more.

ASTM grades meet the standards set by the American Society for Testing and Materials. These standards dictate precise mechanical properties, as well as specific chemistries and testing methods for the steel. ASTM steel specifications are the primary specs used in the United States. The automotive, agriculture, and construction industries each have their own specific requirements as well but they are mostly based on ASTM standards. Siegal works will all of the standards and we are happy to advise you on what grade will work best for your specific industry or application.

"No matter who you're dealing with they are always very helpful"

Steel Processing Services

In addition to the various grades Siegal Offers, like 10b38, we also provide steel processing and services. Click the buckets below to learn more about each process.

Oscillate Winding

The combination of welding several coils in this manner creates one larger and heavier coil than a ribbon wound coil.

Learn MoreSteel Edging

Siegal Steel produces round edge steel strip by precision slitting flat rolled master coils to exact customer specification.

Learn MoreSteel Slitting

Using master coils up to 72” wide, accurate steel slitting produces narrow customer specific widths and winds the cuts back up onto a recoiler.

Learn MoreBarcoding

Bar coding maintains shipment integrity and monitors inventory levels by applying a unique identification number to every unit of your order.

Learn MoreHow Do I Select the Most Appropriate Steel Grade?

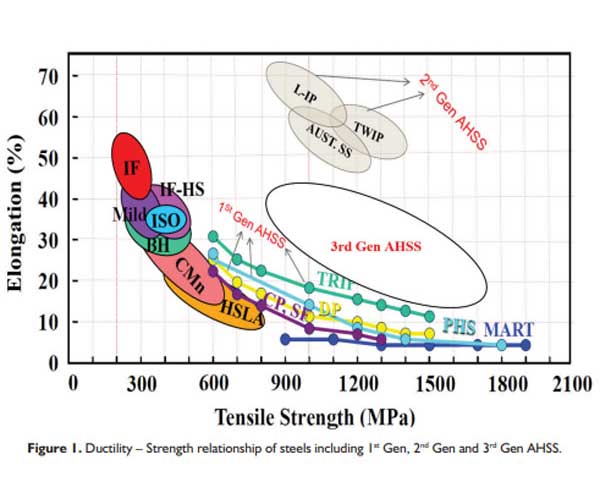

In selecting a steel grade for your application, it is important to keep a few factors in mind, namely: strength, formability, corrosion resistance, weight, chemistry, cost, and recommended uses of that steel. Your need and which of these factors is most important to you will determine the specific grade. Whether you need a steel that is more formable and you can sacrifice on strength, or you need a steel that is highly corrosion resistant but less formable, we can help you find the perfect grade.

Steel strength is measured as a force per unit area to stretching (Yield Strength) or breaking (Tensile Strength), in kilo(1000)-pounds per square inch (ksi), or Mega-Pascal (MPa). 1 ksi is equivalent to 6.9 MPa.

Formability is defined as how much you can stretch the surface before cracks appear and is measured as the % Elongation.

Siegal Steel is happy to personally guide you through the steel selection process. However, should you like to explore on your own, we recommend starting with Commercial Steel. This is a low carbon steel with good strength and formability. It is easy to machine and fabricated, plus it can be securely welded.

What Causes Defects in Steel?

In the process of making steel, it is first melted to form molten steel. Once in this state, elements like sulfur are removed, while elements such as vanadium and boron may be added. The second step involves the addition of elements such as silicon and aluminum. These elements are unique in that they combine with oxygen atoms, forming compounds with high melting temperatures. The addition of these elements is crucial to ensuring oxygen doesn’t form compounds that may melt when the steel is heated for rolling. Both of these types of compounds can remain in the steel as microscopic particles or “inclusions.” The current technology and advancements in steel making have reduced the size and frequency of these inclusions.

After all the necessary elements are added and removed, the molten steel is then cast. Immediately following casting it is either rolled or completely cooled and reheated later for the rolling process. During the casting and rolling process it is possible that surface defects may be introduced. However, these defects that could cause surface cracking and tearing are removed. Siegal Steel will help you select a steel grade that economically meets the internal and surface requirements for your product.

Hot Rolled

Hot-rolled steel is used where precise shapes and tolerances are not required.

Learn MoreCold Rolled

Use Cold-rolled steel where thickness tolerances and surface condition are important for light gauge applications.

Learn MoreStainless Steel

Use Stainless Steel for parts that must resist corrosion by organic acids, weak mineral acids, and weathering by atmospheric oxidation.

Learn MoreMedium and High Carbon Steel

Use in hard and durable parts such as knives, screwdrivers, and hammers. May also be used for construction items.

Learn MoreLow Carbon Steel

Use in structures where large cross-sections are used to minimize deflection, as in large structures.

Learn MoreHigh Strength Low Alloy

Use HSLA steels in cars, trucks, cranes, bridges, and other structures where their high strength-to-weight ratio is most cost-effective.

Learn MoreSpecial Order Products

Established in 1940, Siegal Steel has differentiated itself from other steel processors through quality, service, capabilities and delivery.

Learn MoreReference

Our knowledge and experience give your organization accurate delivery of High Carbon, Low Carbon, Stainless Steel products processed and packaged to your exact specifications.

Have a Question?

Our experts can help

Give us a call at 773-927-7600 or leave us a message.